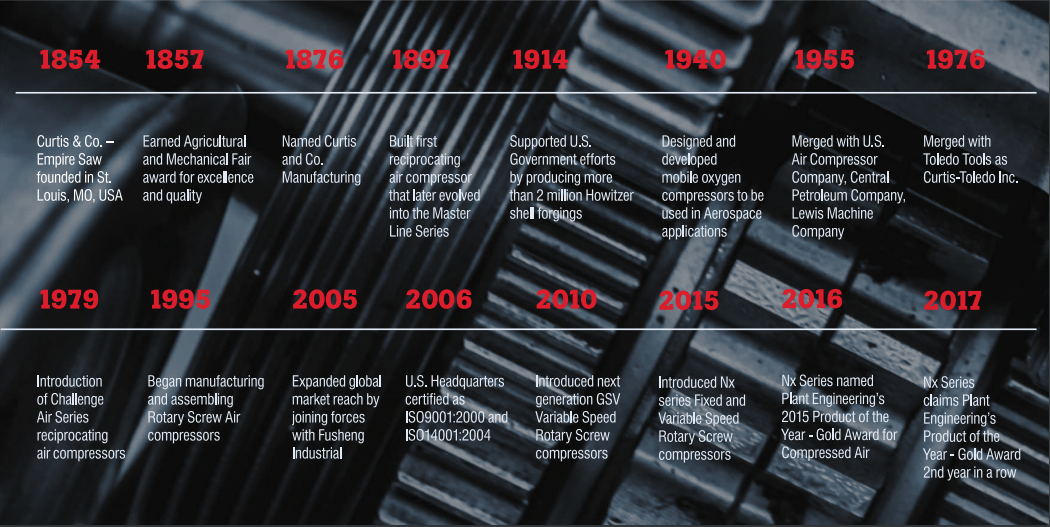

More than 160 years ago, the FS-Curtis way of doing business was established through two key commitments:

a dedication to building quality products and a dedication to responsive customer service.

Over the decades, the company and its products have evolved through innovation and new technologies. But those

commitments to quality and service remain unchanged. Today, just as in 1854, FS-Curtis customers can depend on

our products for reliable, long-term service. Equally as important, they can depend on getting the same from our people.

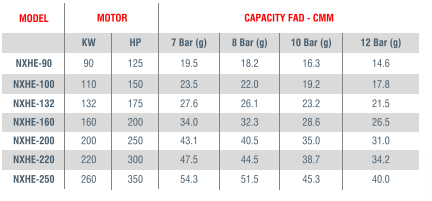

VFD models are available, on request.

Water cooled models are available. details on request.

Just register the machine online, use only FS-Curtis Genuine Parts & Lubricants per the required maintenance schedule,

and you will have peace-of-mind knowing that your machine is backed by the NXGEN Warranty

Extended Warranty Program

All NX products are backed by an industry leading warranty:

Your trusted partner in providing high-quality screw air compressors and industrial solutions.

Copyright 2024 Reserved By Bravity | Website Design With